Relativity Space says it has secured $140 million in new funding from venture capital firms and private investors, enough to carry the company’s 3D-printed small satellite launcher through its first orbital flight from Cape Canaveral in early 2021.

The Series C fundraising round, led by venture capital firms Bond and Tribe Capital, is one of the largest ever for a small satellite launch company. It brings the total amount of funding committed to Los Angeles-based Relativity Space up to $185 million.

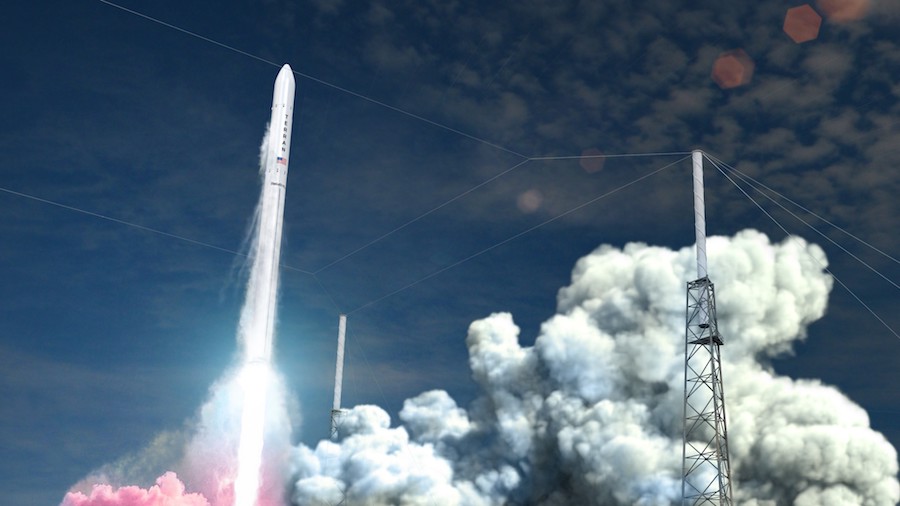

Relativity says its Terran 1 rocket will be the first entirely 3D-printed orbital-class launcher.

“This round will take us all the way past the first flight of Terran 1,” said Jordan Noone, Relativity’s co-founder and chief technology officer.

Actor and musician Jared Leto and billionaire businessman Mark Cuban are among the other investors in Relativity’s latest fundraising round. Cuban was an early supporter of Relativity after the company’s co-founders sent him a cold email, resulting in a $500,000 seed investment.

Relativity Space is in a crowded market, with dozens of companies around the world aiming for a place in the smallsat launch business.

Like Relativity, many of the companies are developing dedicated light-class launch vehicles to carry CubeSats, microsatellites and other small payloads into Earth orbit. At the same time, bigger and established launch companies, like SpaceX, are offering discount rides for small satellite owners who aggregate a large number of payloads on a single rocket.

The small satellite manufacturing and launch business is forecast to nearly quadruple in size over the coming decade, from $12.6 billion between 2009 and 2018 to $42.8 billion from 2019 through 2028, according to the industry research firm Euroconsult. Analysts say the deployment of large numbers of broadband satellites by companies like SpaceX and OneWeb will drive much of the growth, but there are also signs of higher demand in Earth observation, scientific research and space services.

In an interview Wednesday with Spaceflight Now, Noone said the latest $140 million funding was a vote of confidence in Relativity.

“This round is one of the largest that the launch vehicle industry has seen, and one that’s orders of magnitudes more than some of the other people that are in the market as well,” he said. “We’re standing out quite a bit from the rest of the pack in this space.”

The first flight of Relativity’s Terran 1 rocket is planned in early 2021 from Launch Complex 16 at Cape Canaveral Air Force Station in Florida. Earlier this year, Relativity said the Terran 1’s debut orbital launch was scheduled before the end of 2020.

A redesign of the rocket’s payload fairing, which will protect satellites during launch, was the prime reason for the delay, Noone said.

Relativity has scrapped plans for a 2-meter-diameter (6.6-foot) fairing. The company will introduce a new 3-meter-diameter (9.9-foot) fairing design to provide more volume for satellites rising on the Terran 1.

“We’re switching from a 2-meter baseline on the vehicle to a 3-meter baseline for the fairing, based on customer and prospective customer requests and interest there,” Noone said. “It’s an extra capability. It actually almost doubles the payload volume of the vehicle.”

Relativity’s 3D printing production methodology will allow engineers to design and build the new 3-meter fairing more quickly than possible in a traditional rocket factory, according to Noone.

Despite the larger fairing, the Terran 1’s lift capacity will remain unchanged at nearly 2,000 pounds (900 kilograms) to a 310-mile-high (500-kilometer) sun-synchronous polar orbit.

“We were able, on our end, to accommodate this change without a payload impact on the vehicle,” he said. “That was through some slight performance changes on other places on the vehicle.”

“At this scale, you’ll often see customers get volume-constrained, not mass-constrained, on launch vehicles,” Noone said. “That is a unique problem at this scale, where customer payloads will often grow to a size and physical dimension that causes them to outgrow a certain launch vehicle, and us being able to provide that capability, that forward-looking flexibility, is rather valuable.”

Many satellite owners that could launch their payloads on Relativity’s Terran 1 rocket are still refining their spacecraft designs, adding some uncertainty about volume requirements, or how many satellites might fit into a smaller 2-meter fairing.

“If they partnered with another launch vehicle provider, and then had some scope change on their constellation, that actually can completely break their launch plan,” Noone said. “With us, they have a partner that they can start working with, and they can change their design, and we can really chase them through the flexibility of fully 3D-printed rockets, and no one else in the market can match that.”

By the time Relativity launches its first orbital-class rocket, multiple competitors could already be launching regularly. Rocket Lab, a U.S.-New Zealand company with a rocket smaller than Relativity’s Terran 1, began commercial service in 2018.

Virgin Orbit’s air-launched booster could conduct its first orbital test flight before the end of the year, and Firefly Aerospace plans to debut its Alpha rocket in 2020.

Another player in the smallsat launch market, Vector, halted operations in August due to financial troubles.

The Terran 1 will contain 100 times fewer parts than traditional rockets, Relativity says, simplifying and accelerating the timeline to manufacture and assemble the vehicles with 3D printing.

Relativity now has four “Stargate” 3D printers producing test articles for the Terran 1 rocket, and the printers will begin producing flight components next year, Noone said.

“We’re increasing in capacity and physical scale of the printers,” Noone said. “Each printer can do about a foot a day of rocket. With Terran 1 being 105 feet (32 meters) tall, between the four that we have online today, we can actually print an entire rocket structure in less than a month of printer on time. At this phase of the company, we’re actually really happy with the speed we’ve been able to get the printers to run at, but we are on-boarding more printers with more complexity, and actually bigger ones as well.”

Relativity has completed more than 200 hotfire tests of its Aeon engine on test stands at NASA’s Stennis Space Center in Mississippi. Nine methane-fueled Aeon 1 engines will power the Terran 1’s first stage, and a single Aeon engine will fly on the second stage.

Engineers have also completed the Terran 1’s vehicle system design and coupled loads analysis, the company said.

Customers that have announced launch agreements with Relativity to date include Telesat, which plans to use Terran 1 rockets to launch satellites for its low Earth orbit broadband constellation. Spaceflight, a rideshare integrator, has signed an agreement with Relativity for a launch in the second half of 2021, plus options for additional rideshare missions. A Thai company named mu Space also signed a contract to launch a low Earth orbit satellite with Relativity.

“What gives me confidence, and it’s also what gives the customers that have signed with us confidence, is the flexibility because of the tech platform that we are building everything on,” Noone said. “A lot of people have done kind of a race to the bottom as far as getting to first flight as quickly as possible. We’re not, and won’t be the first of our launcher size to fly, but (we’re) the one that customers see to provide a legitimate way to scale up to a quick launch cadence, a legitimate way to learn lessons from flights and introduce those quickly and easily into the launch vehicle, and then also to (respond) to changing customer demands.

“We can provide that flexibility through the 3D printing platform,” he said. “That level of technology underneath the hood of what we do at the company is something that really no other launch vehicle company provides in any form. They do a race to first flight, often not paying any attention to what that looks like afterwards. And that, I think, will actually hurt them very much in the long run.”

Email the author.

Follow Stephen Clark on Twitter: @StephenClark1.