NASA’s Perseverance Mars rover has been hoisted on top of its United Launch Alliance Atlas 5 rocket at Cape Canaveral for liftoff this month, passing a major pre-launch milestone after teams repaired a small leak on the launch vehicle and overcame delays caused by coronavirus cases among staff working on the mission.

The Mars-bound rover was raised on top of the Atlas 5 rocket Tuesday inside ULA’s Vertical Integration Facility at Cape Canaveral Air Force Station. The meeting of the Atlas 5 with the Perseverance rover completed assembly of the 197-foot-tall (60-meter) rocket, which began May 28 with the lifting of the Atlas 5’s first stage on its mobile launch platform.

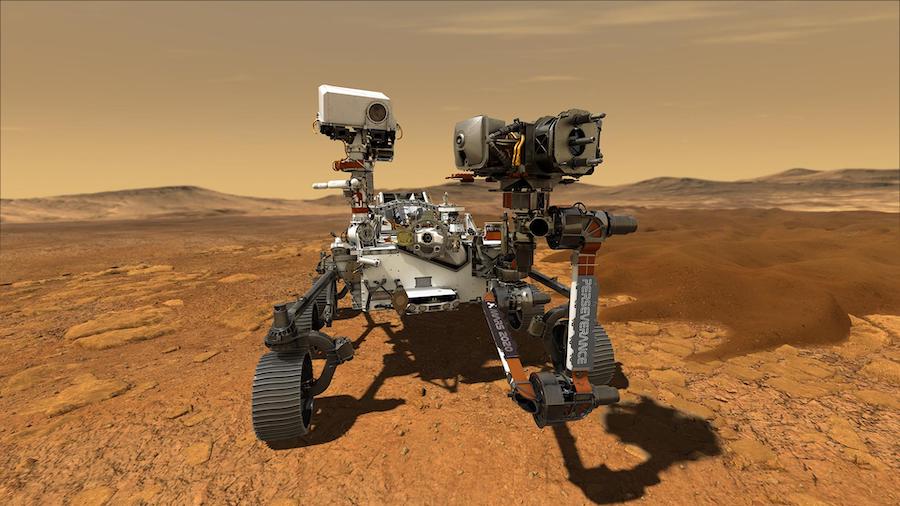

Built by NASA’s Jet Propulsion Laboratory in California, the rover will land on Mars on Feb. 18, 2021, and begin exploring a region named Jezero Crater. The 28-mile-wide (45-kilometer) crater was once home to an ancient river delta, and the Perseverance rover will collect rock and soil samples for eventual return to Earth by a future robotic mission.

Omar Baez, NASA’s launch director for the Perseverance mission, said Wednesday that the launch is on track for July 30. The launch window opens at 7:50 a.m. EDT (1150 GMT), with launch opportunities available at five-minute intervals.

“It’s good to make some forward progress,” Baez said in an interview with Spaceflight Now.

The launch was originally scheduled for July 17, the opening of an interplanetary launch period that extends into mid-August. But several issues, including suspected and confirmed coronavirus cases among team members, have slowed preparations for the launch, Baez said Wednesday.

In late May, ULA encountered trouble with a hydraulic erector used to rotate the Atlas 5’s strap-on solid rocket boosters vertical before attachment around the vehicle’s first stage. That caused a delay of a couple of days before ULA resolved the problem and resumed installing the solid rocket boosters and the Atlas 5’s Centaur upper stage, according to Baez.

Meanwhile, the Perseverance rover, its landing system and cruise stage — essentially three different spacecraft making up $2.7 billion NASA’s Mars 2020 mission — were prepared for launch inside the Payload Hazardous Servicing Facility at NASA’s Kennedy Space Center. The final steps to ready the rover for mating with the Atlas 5 rocket involved enclosing it inside its aerodynamic shell, which will protect it during entry into the Martian atmosphere, and then encapsulating the craft inside the Atlas 5’s payload fairing.

“We were working simultaneously on getting the spacecraft encapsulated, and we ran into some issues with the crew,” Baez said. “A couple of the folks were suspected of having COVID, and actually had COVID, and with the precautions that come with that, anybody that’s been in close proximity to those folks either get tested or choose to stay out of work for however long they think is safe under the current guidelines.”

Citing medical privacy concerns, Baez declined to say whether the coronavirus cases were with employees from the Kennedy Space Center, the Jet Propulsion Laboratory, or ULA. But he said the contract tracing and quarantine stemming from the COVID-19 cases impacted “everybody working on the payload,” including employees from all three organizations.

Launching a mission to Mars is hard enough in normal times, Baez said, but doing it amid a pandemic adds an extra layer of difficulty.

“Unfortunately, it did cost us a couple of days,” Baez said. “We did have some other problems along the way, not only crew, but we had some contaminated air lines in the facility where we process (the spacecraft) … That got into some of the hoisting mechanisms that we use to lift the spacecraft up onto the payload adapter before we go and encapsulate it.

“We got through those things, got the crew back and healthy and able to do the encapsulation, and we were able to successfully go out to the launch pad yesterday,” Baez said Wednesday.

Teams also encountered a problem with a liquid oxygen sensor line on the Atlas 5 rocket. Engineers discovered the issue during a countdown rehearsal June 22, during which ULA filled the Atlas 5 with kerosene, liquid hydrogen and liquid oxygen propellants to put the rocket through a thorough checkout before launch day.

The exercise proved useful in revealing the liquid oxygen sensor line problem, and ULA inspected the rocket once it rolled back to the Vertical Integration Facility after the countdown rehearsal.

“We were hoping that it was as simple as a loose fitting, but the area where (the sensor line) resides does have one area in particular where there’s a very thin-walled tube that has to get welded,” Baez said.

Super-cold cryogenic fluid never passes through the sensor line until the Atlas 5 is filled with propellant. That makes it challenging to detect leaks before the countdown rehearsal or the countdown itself on launch day.

“It did reveal itself as a pinhole leak in the weld,” Baez said.

A welder from ULA’s rocket factory in Decatur, Alabama, traveled to Cape Canaveral to address the problem. The configuration of the sensor line while the rocket is standing vertical made the work challenging, with the welder entering a cavity inside the rocket and working “upside down” near the Centaur upper stage’s engine section, Baez said.

“It’s kind of a tricky way to weld,” Baez said. “It’s a pretty tight area there for the guy to be working.”

With the Perseverance rover mounted on the Atlas 5 rocket, ULA and NASA engineers are kicking off a series of checkouts to ensure a good electrical and data path between the payload and launcher. An integrated systems test is set to begin Thursday inside the VIF.

According to Baez, teams will work the next two weekends to keep the launch on schedule for July 30. If everything goes according to plan, workers will take a couple of days off to “reset” before the Atlas 5 and Perseverance rover are scheduled to roll from the VIF to Cape Canaveral’s Complex 41 launch pad July 28.

With summertime thunderstorms common on Florida’s Space Coast, and unknowns associated with the coronavirus pandemic, Baez said officials might end up needing the extra couple of days to complete tasks before the July 30 launch date.

Another significant step to prepare for launch will be the attachment of the Perseverance rover’s plutonium power source. The Multi-Mission Radioisotope Thermoelectric Generator will be installed through a port on the Atlas 5’s payload fairing.

A flight readiness review is planned July 22, followed by a launch readiness review July 27 to give approval for rollout to the launch pad the following day.

The launch period for the Mars 2020 mission originally ended Aug. 5, but NASA said earlier this month that additional analysis of the rover’s trajectory extended the available launch dates through Aug. 11. On Tuesday, NASA said flight analysis teams have added more days to the launch period, which now extends to Aug. 15.

Baez said the Mars 2020 spacecraft weighs a little less than originally expected, allowing engineers to use some of the Atlas 5’s performance margin to extend the launch window later into August. Mission planners can also gain extra launch dates by reducing the length of the window available each day.

If necessary, Baez said he expects trajectory analysts could extend the launch window through at least Aug. 17, if required. After August, the next chance to launch the Perseverance rover after this August will come in 2022.

“When you talk about Earth and Mars being on the same side of the sun, that happens once every 26 months,” said NASA Administrator Jim Bridenstine in a Mars 2020 pre-launch press conference last month. “So it’s very expensive, if we have to take Perseverance and put it back into storage for a period of two years, it could cost half a billion dollars.”

Email the author.

Follow Stephen Clark on Twitter: @StephenClark1.