CAPE CANAVERAL — Meet the Vulcan, the next-generation rocket family brought to you by United Launch Alliance that comes with a bold reusability plan, multiple configurations for medium- to heavy-lift, all-American engines and serves as the eventual replacement for the historic Atlas and Delta rocket lines.

ULA boss Tory Bruno took the wraps off the company’s future today in a visionary presentation in Colorado, laying out a technological architecture roadmap through 2035.

“Because the Next Generation Launch System will be the highest-performing, most cost-efficient rocket on the market, it will open up new opportunities for the nation’s use of space,” Bruno said.

“Whether it is scientific missions, medical advancements, national security or new economic opportunities for businesses, ULA’s new Vulcan rocket is a game-changer in terms of creating endless possibilities in space.”

The new rocket follows 20 years after the last major revolution in the U.S. launch industry introduced the Evolved Expendable Launch Vehicles — Atlas 5 and Delta 4 — for the U.S. Air Force.

ULA, a 50-50 joint venture of Boeing and Lockheed Martin, blended the two rockets into a combined cooperative team in 2006, and has flown 96 times since then, all successfully.

Vulcan, slated for its maiden launch in 2019, will be powered by either a pair of exotic Blue Origin BE-4 liquefied natural gas main engines for 1.1 million pounds of thrust or two conventional Aerojet Rocketdyne AR-1 kerosene powerplants for a million pounds of thrust. A final decision of which engine to pursue will come next year.

The new rocket ditches the Atlas-used RD-180 main engine produced in Russia. The engine has brought controversy to the vehicle and its launchings of U.S. national security payloads using foreign-made propulsion.

Creating the new first stage with an American engine is the overarching priority for ULA. The development of a new upper stage will follow later to replace the venerable Centaur that will be flown on Vulcan initially.

“We are doing our whole new rocket in serial steps so that we can afford that development process,” Bruno said.

Bringing Vulcan to the launch pad will take a four years and substantial investment. “We don’t talk about exactly how much we are spending,” Bruno added, but developing a new engine, historically, has cost $1 billion and a new rocket endeavor is around $2 billion.

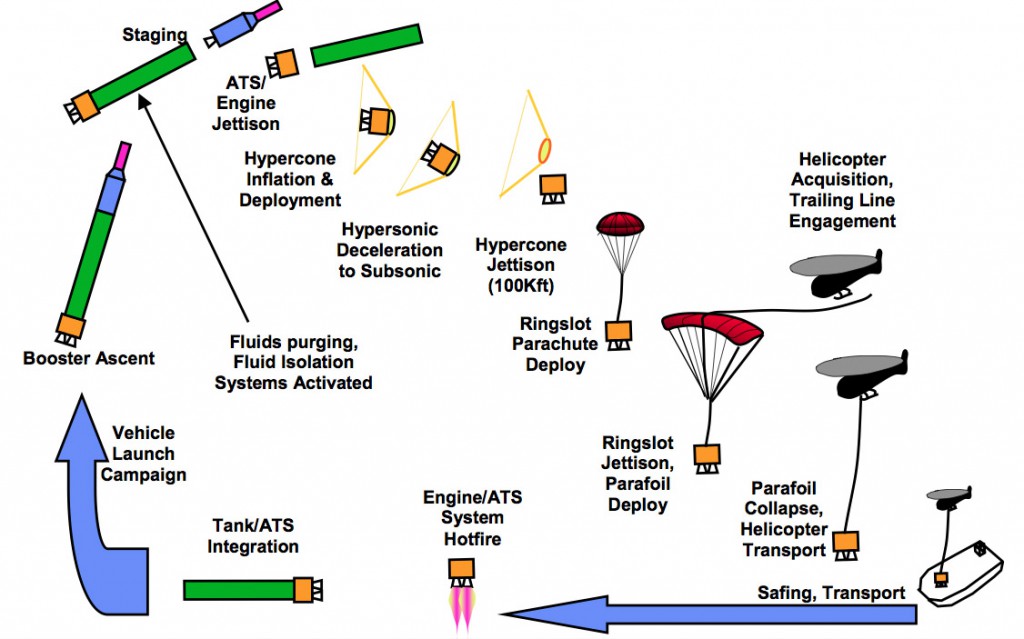

Reusability will be part of the new launcher, just not at first. A mid-air recovery of the vehicle’s main engines and thrust section will be used to retrieve and reuse the powerplants, the most valuable pieces of equipment on the first stage.

“It does not appear on the first flight, we add it later,” Bruno said.

“For the next decade or so, what really is going to drive reusability is not frequency (of flights), but the pure economics of it. Can you do it less expensively with reusability than with an expendable approach?” Bruno asked.

“What something weighs drives how hard it is and how expensive it is to recover it. As it turns out, the things that weigh the most are not the things most valuable on the rocket. Our concept for reusability is inside that mathematics and realizes that maybe reusability does not start with entire stages, but there are things on it that are expensive and not that hard to get back and a lot easier to reuse a number of times. Maybe that’s the right way to approach reusability.”

ULA envisions a Vulcan flight rate capable of 10 to 20 flights per year, offering the cost for the entry-level rocket at $100 million. An Atlas 5 today costs $164 million.

“Our basic Atlas 401-equivalent in Next Generation Launch System, which will sort of be comparable to a Falcon but with more capability, will be about $100 million per launch service,” Bruno said.

“When we plan our factory and talk about numbers like this, we always assume we are at a minimum of 10 flights per year. That’s where the knee in the curve breaks for economical order quantities coming through our rocket factory.”

Ups and downs of the market

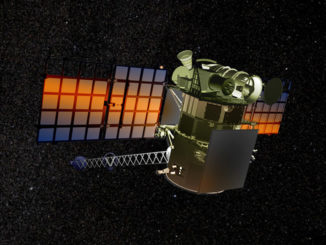

While the current ULA manifest is nearly maxed out with national security missions, forecasters see a throttling back coming as new satellite constellations such as the Wideband Global SATCOM and AEHF satellites finish their deployments.

“The national security market has a big dip in it in the 2018-2022 timeframe. We are going from a time when the Air Force and NRO flew 10 times a year to more like five,” Bruno said.

“We are going to be filling back in with civil missions for NASA, we already do NASA’s most challenging science missions like New Horizons and Solar Probe Plus, but also commercial crew and commercial cargo. And we will be doing commercial, which is primarily commercial telecommunications with some commercial Earth-observation as well.”

Dial-a-rocket approach continues

Like the EELV rockets before it, Vulcan will be a modular vehicle and offer a tailor-fit to whichever payload it is launching, with different size nose cones or strap-on boosters to incrementally increase performance as needed.

It is that flexibility and multiple rocket configuration options that sets ULA’s product apart from others in the industry. SpaceX, for example, has only its entry-level Falcon 9 and the not-yet-flown Heavy version and Arianespace goes from Vega to Soyuz to Ariane 5. Vulcan will come in a dozen variants from medium- to heavy-lift.

With the basic vehicle to a high-performance rocket, ULA says Vulcan will be able to launch the full spectrum of national security payloads, just like the EELV rockets have done. They have launched satellites as small as 2,700-pound Air Force weather observatories to massive, classified National Reconnaissance Office payloads, plus everything in between.

The Vulcan will come with either a four- or five-meter nose cone to encapsulate the cargos. The four-meter version can be outfitted with no solids or as many as four to added liftoff thrust. The five-meter version can fly with as many as six solids, making it equivalent to the Delta 4-Heavy rocket.

Step No. 2 in the Vulcan development process will be the new upper stage. Known as the Advanced Cryogenic Evolved Stage, or ACES, it will offer extended mission durations and be powerful enough to replace the Delta 4-Heavy for its most-challenging NRO missions to directly into geosynchronous orbit 22,300 miles above the Earth.

The balloon-tanks of the stage will be fitted with one-to-four engines from either Aerojet Rocketdyne, XCOR or Blue Origin, the down-select to be made later. It will launch in 2023.

Launch sites to be determined

The final ruling on which launch pads will be used for Vulcan is a couple months away, Bruno says. There will be sites at both Cape Canaveral in Florida and Vandenberg Air Force Base in California.

“Have we decided exactly which pads? No, not yet,” he said in an interview last week.

The Cape launches to the east, achieving equatorial-type orbits for such payloads as communications satellites and to the northeast to reach the International Space Station.

In contrast, the geography allows Vandenberg to service polar orbits for main science satellites and reconnaissance platforms.

‘Thoughtful’ reusability

“Reusable stages have been looked for a long time by an awful lot of folks. When you do an all-up stage recovery, the economics can be challenging because you’ve got to recover it close to 7 times to break even on costs,” Bruno said in an interview.

“When you do that, the cost vs. reuse curve — it’s not a straight line, it’s not like ‘oh, I got to use it twice so now it’s half as much.’ It doesn’t work that way because the rocket itself, if it’s built for reuse, is more expensive than a rocket built for single use.

“You have to recover and refurbish, and all those things cost. So you save money in reusability as a function of how many times you can reuse it. You have to fly 7 times to break even and get out to 14-15-16 times to get a decent return.

“You’re not going to go through all that energy and risk, 20-30 percent performance loss just to be equivalent to an expendable. You actually want to come out ahead.

“Conventual technologies on a booster, like you see other people doing, and being able to recover and reuse that booster 15 times with relatively minimal refurbishment costs, that’s pretty darn challenging and maybe not the right place, in our view, to work on that problem.”

So ULA’s plan, using third-generation mid-air recovery technology, will see the bottom of the rocket disengage after doing its powered flight, decelerated with a hypersonic heatshield in the upper atmosphere and parachute down to be intercepted by a waiting helicopter for capture.