Watch a replay of our live coverage of the countdown and launch of Relativity Space’s first 3D-printed Terran 1 rocket. The Terran 1 lifted off from Launch Complex 16 at Cape Canaveral Space Force Station, Florida, on its inaugural test flight at 11:25 p.m. EDT Wednesday, March 22 (0325 UTC Thursday, March 23). Follow us on Twitter.

Relativity Space, a company with ambitions to develop a fully reusable rocket, launched its first expendable methane-fueled booster from Cape Canaveral Wednesday night, successfully demonstrating the strength of the launcher’s first-of-its-kind 3D-printed structure but failing to reach orbit after a malfunction on the test flight’s second stage.

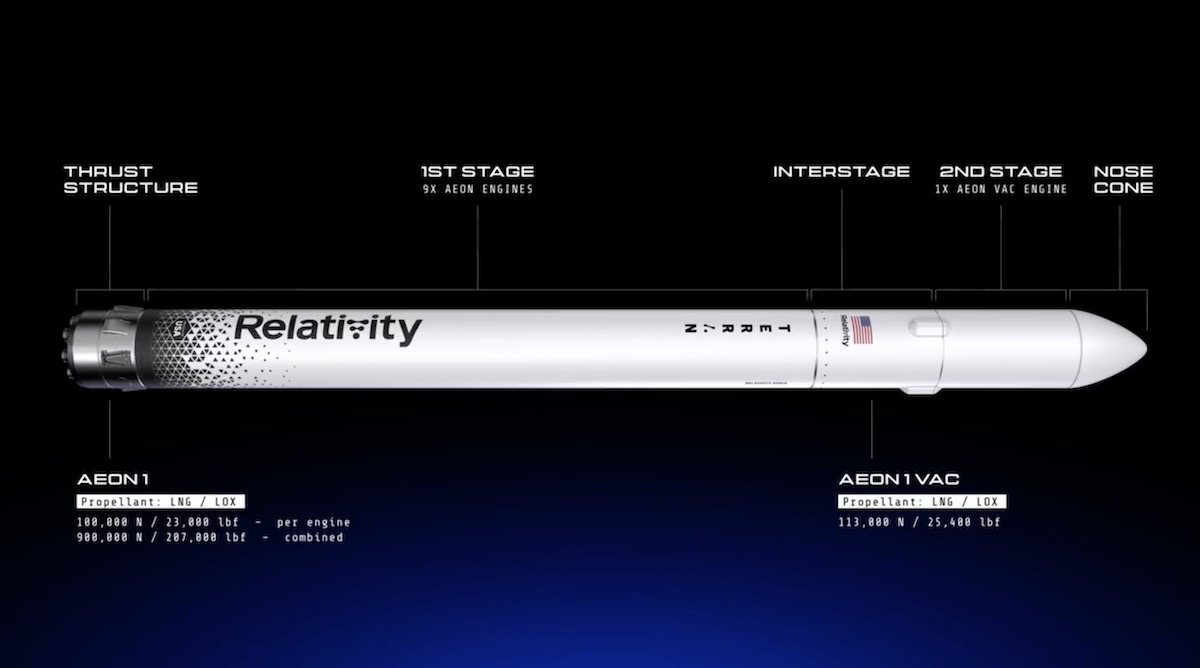

The two-stage rocket, called the Terran 1, is the first orbital-class launcher primarily manufactured with 3D printing, and the first U.S.-made launch vehicle of its size to use methane as a fuel. The initial phase of the Terran 1’s inaugural flight Wednesday night appeared to go according to plan, with no problems reported until the second stage was supposed to ignite nearly three minutes after liftoff.

The upper stage’s Aeon engine was supposed to ignite for a five-minute burn to accelerate the rocket to orbital velocity, around 17,000 mph. But a camera on the second stage showed intermittent flames from the engine, which did not appear to power up to full thrust. The rocket reached a top speed of about 4,600 mph (7,400 kilometers per hour) then started slowing down as it briefly soared into space, according to a velocity reading on Relativity’s live webcast of the test flight.

Relativity’s launch director, Clay Walker, confirmed there was an anomaly on the second stage in an announcement around five minutes into the mission.

The upper stage engine on Relativity Space’s Terran 1 rocket appeared to sputter shortly after ignition on tonight’s test flight

The company confirmed an anomaly with the upper stage, and the Terran 1 will not reach orbit on its first-ever launchhttps://t.co/5SAWJ1O3G3 pic.twitter.com/SJiMpYQmOZ

— Spaceflight Now (@SpaceflightNow) March 23, 2023

There were no satellites on the Terran 1 rocket’s first test flight. Debris from the rocket likely fell into the Atlantic Ocean around 400 miles east of Cape Canaveral.

Relativity Space, a California-based startup founded in 2015, said before the Terran 1 test flight that one of its main objectives with the test flight was to demonstrate a 3D-printed rocket could withstand the extreme vibrations and forces of a launch, particularly in a phase of the flight known as Max-Q, or maximum aerodynamic pressure. The data gathered on the Terran 1 test flight Wednesday night will aid in the development of Relativity’s future rocket, a fully reusable launcher named Terran R, the company said.

“Maiden launches are always exciting, and today’s flight was no exception,” said Arwa Tizani Kelly, Relativity Space’s technical program manager for test and launch. “Although we didn’t reach orbit, we significantly exceeded our key objectives for this first launch, and that objective was to gather data at Max-Q, one of the most demanding phases of flight, and achieve stage separation. Today’s flight data will be invaluable to our team as we look to further improve our rockets, including Terran R.”

Ground testing before the Terran 1’s first launch showed the 3D-printed rocket could withstand similar forces as a launch vehicle built with more conventional materials, like aluminum, carbon fiber, or stainless steel. The flight test Wednesday appeared to confirm those findings.

In a statement posted on Twitter, Relativity said the Terran 1 rocket’s survival through Max-Q was the “biggest proof point for our novel additive manufacturing approach.”

“Today is a huge win, with many historic firsts,” Relativity said. “We also progressed through main engine cutoff and stage separation. We will assess flight data and provide public updates over the coming days.”

Here’s a replay of Relativity Space’s first Terran 1 rocket from Cape Canaveral at 11:25pm EDT (0325 UTC).

The methane-fueled, 3D-printed rocket climbed into space powered by nine main engines, but an upper stage failure prevented it from reaching orbit.https://t.co/5SAWJ1O3G3 pic.twitter.com/YoK79nmM5C

— Spaceflight Now (@SpaceflightNow) March 23, 2023

Relativity’s first Terran 1 rocket lifted off at 11:25 p.m. EDT Wednesday (0325 UTC Thursday) from Launch Complex 16 at Cape Canaveral Space Force Station after scrubbing two countdowns earlier this month.

Strong upper level winds and a boat that strayed into the launch hazard area in the Atlantic Ocean delayed liftoff of the 110-foot-tall (33.5-meter) Terran 1 rocket by nearly an hour-and-a-half Wednesday night. But with those issues cleared, Relativity’s launch team picked up the countdown and stepped through a final series of check before handing over control of the launch sequence to computers.

Nine methane-fueled Aeon 1 engines, designed and built by Relativity, ignited six seconds before launch and throttled up to full power, producing 207,000 pounds of thrust. After a last-second health check, the rocket’s computer gave the command to release hold-down restraints and the Terran 1 climbed away from Relativity’s launch pad.

The nine main engines produced a blue-tinted exhaust flame as the Terran 1 soared into the atmosphere, steering on a path east from Cape Canaveral before surpassing the speed of sound about a minute into the mission. The next key test came at T+plus 80 seconds, when the rocket reached Max-Q.

The Aeon 1 engines on the first stage shut down at T+plus 2 minutes and 40 seconds, followed moments later by release of the first stage booster. Then the upper stage was supposed to ignite its engine to power the Terran 1 rocket to orbital velocity.

But the rocket’s speed started dropping, and Relativity declared a premature end to the test flight.

The Terran 1 rocket is designed to haul more than a ton of cargo into low Earth orbit. The rocket is aimed at the commercial launch market for small to mid-sized satellites, making Relativity one of several privately-developed smallsat launch companies coming online in the last few years.

Relativity Space got within a half-second of launching the Terran 1 rocket on the second launch attempt March 11.

The company said the countdown automatically aborted when a computer detected a problem just a half-second before liftoff. Ground teams uplinked new software to the rocket to fix the glitch, then tried again to launch the Terran 1 rocket later in the launch window March 11. But the countdown stopped again at T-minus 45 seconds when computers detected a slightly low pressure in the second stage methane fuel tank.

Engineers called off a previous launch attempt March 8 when a ground system problem prevented the rocket’s cryogenic liquid oxygen from reading the proper temperature.

After software tweaks and slight changes to the countdown sequence, Relativity was ready to try again Wednesday night.

If the Terran 1 rocket completed its eight-minute flight without incident Wednesday night, it would have become the first methane-fueled launcher to reach orbit in history, beating two much larger rockets — United Launch Alliance’s Vulcan and SpaceX’s Starship — scheduled to attempt their first full-scale test flights in the coming weeks or months.

Tim Ellis, co-founder and CEO of Relativity Space, said methane is the “propellant choice of the future, especially for reusable rockets.”

Methane is a more efficient fuel than kerosene, which is used on SpaceX’s Falcon 9 rocket, Russia’s Soyuz launcher, and ULA’s Atlas 5. It also burns cleaner and leaves less residue inside an engine than kerosene, easing refurbishment and reuse between missions.

Before the first Terran 1 even left the launch pad, Relativity started development of a larger fully reusable rocket called the Terran R, a vehicle the company says will become a “point-to-point space freighter capable of missions between the Earth, moon and Mars.”

Despite the lofty ambitions with Terran R, the first test flight of the more modest Terran 1 rocket was a major milestone for Relativity, a company founded in 2015 by Ellis and Jordan Noone, college classmates who worked short stints as engineers with Blue Origin and SpaceX. Ellis, 32, is CEO of Relativity, while 30-year-old Noone stepped down as the company’s chief technology officer in 2020.

The company now boasts some 1,000 employees, a million-square-foot headquarters and factory in Long Beach, California, and $1.3 billion in venture capital and equity fundraising, including an early $500,000 investment from billionaire Mark Cuban. In 2021, the company reached a valuation of $4.2 billion before launching any rockets.

Josh Brost, Relativity’s vice president of revenue operations, told Spaceflight Now before the Terran 1 launch that getting to orbit on the first try would not “define success” for the company.

“There are many other things that could happen on launch that would still be considered very successful for us,” Brost said in an interview.

Brost said getting through Max-Q on the first Terran 1 launch would show “not just to ourselves, but to the world, a 3D-printed rocket is really up to the to the task of taking on those launch environments.”

The Terran 1 rocket can carry up to 2,755 pounds, or 1,250 kilograms, of cargo to a low-altitude orbit. That’s significantly more than other commercial small satellite launchers, such as Rocket Lab’s Electron vehicle. Relativity says it sells a dedicated launch on a Terran 1 rocket for $12 million, about twice the price of a flight on the smaller Rocket Lab vehicle.

Relativity Space not only developed the Terran 1 rocket and designed the Aeon rocket engine from scratch, the company has also introduced four generations of 3D printers, each capable of building more rocket components faster and at lower cost.

About 85% of the 20,458-pound (9,280-kilogram) structural mass of the Terran 1 rocket was manufactured with 3D printing technology, including its Aeon engines. 3D printing allows Relativity to manufacture rockets with 100 times fewer parts than launch vehicles built using conventional methods, the company says.

Relativity produced the Terran 1 rocket’s primary structure and propellant tanks on its 3D printers using a proprietary aluminum alloy. The engine thrust chambers, injectors, and turbopumps, reaction control thrusters, and pressurization systems also rely on 3D printing tech. Other parts, such as avionics and flight computers, were manufactured using conventional methods, Brost said.

A company spokesperson said extensive rocket testing at Cape Canaveral and on a test stand at NASA’s Stennis Space Center in Mississippi gave officials enough confidence to proceed with the Terran 1 launch, despite not completing a full-duration test-firing of the first stage as originally planned. The engines and the Terran 1’s autogenous pressurization system, which uses self-generated gases to maintain pressure in the propellant tanks, performed well during the recent ground testing, Relativity said.

“We were very intentional about trying to get to the pad as fast as we could to maximize the rate of learning,” Brost said.

Overall, Relativity has completed 191 Aeon 1 hotfire tests with 10,900 seconds of run time during engine qualification and acceptance testing on a firing stand at Stennis Space Center.

The second stage of the Terran 1 rocket, powered by a single “Aeon Vac” engine optimized for firings in space, completed a full “mission duty cycle” simulating the burn it will perform on the test flight. Relativity also completed structural loads testing on the first and second stages of the Terran 1 rocket, and functional testing on stage separation and other “flight-critical” mechanisms.

Relativity also completed a “mission duty cycle” test of the Terran 1’s second stage in Mississippi, before shipping it to Florida for launch preparations. The mission duty cycle ran the entire upper stage, including the engine, through a test sequence matching what it would experience in flight.

The Terran 1 rocket’s departure point, Launch Complex 16, is a long-dormant facility at Cape Canaveral once used by Titan and Pershing missile tests, and test-firings of NASA’s Apollo service module engine. Launch Complex 16 was last used for a launch in 1988, and is located on the historic “missile row” at Cape Canaveral, south of United Launch Alliance’s Delta 4 launch pad and north of SpaceX’s rocket landing zone.

After announcing in 2016 it received the military’s approval to use Launch Complex 16, Relativity built a rocket processing hangar, erected lightning protection towers, and installed propellant holding tanks at the site.

Relativity delivered the Terran 1 rocket to Cape Canaveral last June for final integration and testing.

The due east trajectory from Cape Canaveral after Wednesday night’s liftoff aimed to place the Terran 1 rocket into a low-altitude orbit inclined 28.5 degrees to the equator, the same latitude as the Florida spaceport.

One thing the Terran 1 rocket was not testing on Wednesday night’s mission was a payload fairing, the aeroshell that protects satellites during a rocket’s initial climb through the atmosphere, then jettisons to reveal the payloads after they reach space. The Terran 1 used on Relativity’s first test flight had an aerodynamic nose cone, which was not designed to separate from the rocket.

A 6-inch-wide metal ring, one of the first test articles Relativity printed several years ago, was riding inside the Terran 1’s nose cone as a token payload.

The decision to forego flying a payload fairing on the Terran 1’s first test flight was simply to ensure the company kept its focus on the parts of the rocket that have to work to reach orbit, Brost said.

“If you look at how new rockets fail, there’s a number of different failure modes where systems can run into trouble,” Brost said in a pre-launch interview. “Those are really where we’re focusing our efforts.

“That’s putting our effort into massive amounts of propulsion testing and significant amounts of on-ground, hardware-in-the-loop avionics testing, and full end-to-end structural testing to make sure that the system has the best chance of getting all the way to orbit, and gives us the best chance to collect massive amounts of data that we can then use to improve our systems going forward,” Brost told Spaceflight Now before the launch.

Relativity has a launch contract with NASA to fly a cluster of small satellites on the second Terran 1 mission from Cape Canaveral. The company also has a contract with Telesat to launch satellites for that company’s planned low Earth orbit internet constellation. And Iridium has a long-term agreement to launch voice and data relay satellites on Relativity’s rockets.

Last year, Iridium shifted the launch of five of its remaining six spare “Iridium Next” satellites from multiple dedicated flights on Relativity’s Terran 1 rocket to a rideshare mission later this year on a single SpaceX Falcon 9 rocket. “We still have one ground spare left, which could launch in the future on the Terran 1,” an Iridium spokesperson said.

But Iridium says its contract with Relativity includes provisions to use the launch company’s future systems, like the Terran R. OneWeb has also signed a multi-launch agreement to fly its second-generation broadband satellites on Terran R rockets. And another startup space company, called Impulse Space, announced last year it plans to send a robotic lander to Mars with a boost from Relativity’s Terran R.

Relativity says it has a contract backlog with a dozen customers worth more than $1.65 billion. The majority of the backlog is for missions to launch on the larger reusable Terran R, which Relativity says could launch for the first time by the end of 2024. Like the Terran 1, the Terran R will be constructed with 3D-printing technology, use methane fuel, and will depart for space from Launch Complex 16 at Cape Canaveral.

In a Twitter thread posted on the eve of the Terran 1’s first launch, Ellis signaled Relativity is eager to shift its efforts to developing the Terran R.

“Medium-heavy lift is clearly where the biggest market opportunity is for the remaining decade, with a massive launch shortage in this payload class underway,” Ellis said.

Resembling a smaller version of SpaceX’s giant Starship rocket, the Terran R will stand 216 feet (66 meters) tall and measure 16 feet (5 meters) in diameter.

Flying in reusable mode, the Terran R rocket will be capable of delivering a payload of 20 metric tons, or 44,000 pounds, to low Earth orbit, according to Relativity. The payload capacity could increase if Relativity flew the Terran R as an expendable rocket.

The Terran R first stage will be powered by seven reusable 3D-printed Aeon R engines capable of 302,000 pounds of thrust each, combining to generate 2.1 million pounds of thrust at full throttle. The Terran R second stage will have one Aeon Vac engine.

Other new commercial launch providers that initially developed a small satellite launcher, such as Rocket Lab and Firefly Aerospace, are also pivoting to larger rockets. Rocket Lab is developing the partially reusable Neutron rocket, and Firefly is in the early stages of a partnership with Northrop Grumman to develop a medium-class launch vehicle.

Ellis tweeted that Relativity will look to its customers for guidance on whether to continue testing and flying the Terran 1, or to move on to the Terran R.

“Our customers will really be our deciding jury,” Ellis said before the Terran 1 test flight. “They may view this launch as a success once we prove the vehicle’s structural integrity at Max-Q, but they may also be looking to later stages of flight, like stage separation, and then 2nd stage engine ignition.”

“If on our inaugural Terran 1 launch we encounter issues that are more commonplace with rocket launches — rocket science problems and not additive-related problems — we’ll ask those customers for input,” Ellis said. “Do they want us to continue down the path of producing more Terran 1s to solve for those issues on this vehicle? Or would (they) like us to solve the remaining rocket science problems on the vehicle they are actually most interested in, Terran R?”

The Terran 1 is a “fantastic learning platform for developing developing technologies directly applicable to Terran R, giving us a lot of confidence we are ahead in the race to become the next great launch company,” Ellis said.

ROCKET: Terran 1

PAYLOAD: “Good Luck, Have Fun” test flight; No customer payload

LAUNCH SITE: LC-16, Cape Canaveral Space Force Station, Florida

LAUNCH DATE: March 22/23, 2023

LAUNCH TIME: 11:25 p.m. EDT on March 22 (0325 UTC on March 23)

WEATHER FORECAST: 95% chance of acceptable weather

BOOSTER RECOVERY: None

LAUNCH AZIMUTH: East

TARGET ORBIT: 124 miles by 130 miles (365 kilometers by 373 kilometers), 28.5 degrees inclination

LAUNCH TIMELINE:

- T+00:00: Liftoff

- T+00:12: Pitch downrange

- T+01:20: Maximum aerodynamic pressure (Max-Q)

- T+02:40: First stage main engine cutoff (MECO)

- T+02:45: Stage separation

- T+02:51: Second stage engine ignition

- T+07:43: Second stage engine cutoff (SECO)

- T+08:00: Terran 1 in orbit

MISSION STATS:

- 1st launch by Relativity Space

- 1st launch of Terran 1 rocket

- 151st launch from Launch Complex 16

- 15th orbital launch attempt based out of Cape Canaveral in 2023

Email the author.

Follow Stephen Clark on Twitter: @StephenClark1.