NASA ground crews at the Kennedy Space Center are continuing to stack segments of the Space Launch System’s side-mounted solid rocket boosters on a mobile launch platform inside the iconic Vehicle Assembly Building.

The joints connecting each piece of the five-segment rocket motors are certified for one year once booster stacking begins, a clock that began ticking Jan. 7 with the hoisting of the SLS’s left-hand aft center booster segment on top of the booster’s lowermost piece.

But the 12-month certification limit, a holdover from the space shuttle program, could be extended with an engineering review, according to John Honeycutt, NASA’s Space Launch System program manager at the Marshall Space Flight Center in Alabama.

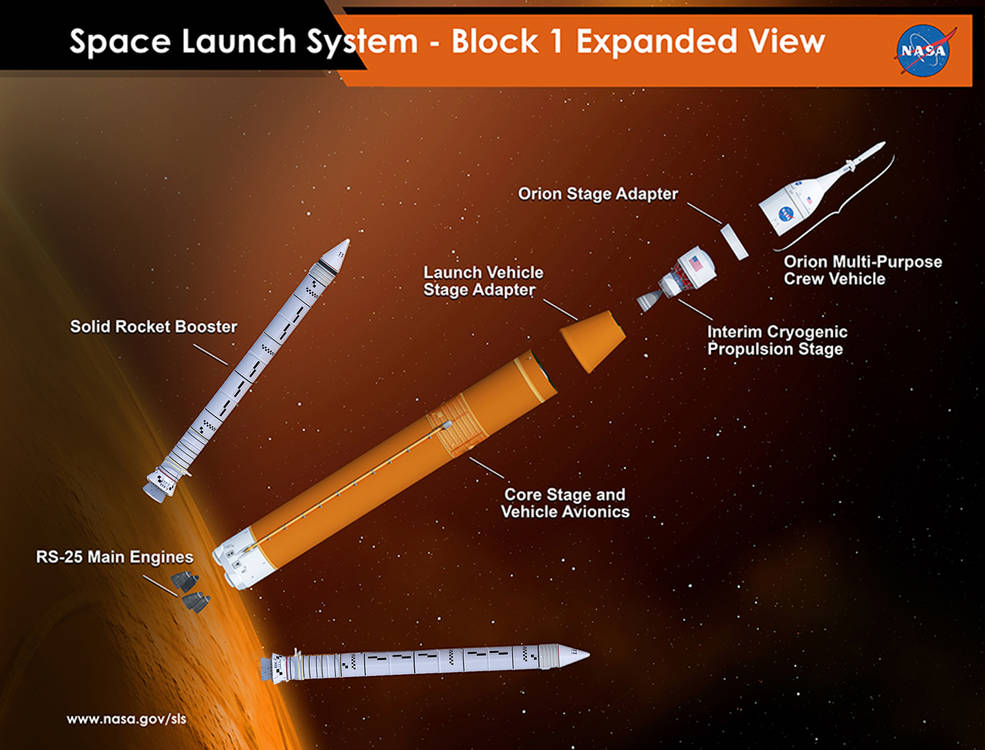

The SLS boosters are derived from the space shuttle’s solid rocket motors, and segments flying on the first SLS test launch have been refurbished from the shuttle program. The Northrop Grumman-built solid rocket boosters on the Space Launch System have five segments, while the shuttle’s boosters had four segments with pre-packed solid propellants.

The extra segment gives the SLS boosters more thrust during launch.

Honeycutt said Jan. 12 that NASA decided to move forward with booster stacking at Kennedy before the test-firing of the SLS core stage at the Stennis Space Center in Mississippi. The hot fire test is planned Saturday at Stennis, followed by delivery of the core stage to Kennedy by barge before the end of February.

Ground crews with NASA and Jacobs, the space agency’s ground systems contractor at Kennedy, began stacking the five-segment boosters on the SLS mobile launch platform Nov. 20. Teams paused stacking operations after installing the aft booster assemblies, which include the rocket nozzles, on the mobile launch platform to wait for completion of a cryogenic tanking test on the SLS core stage in Mississippi.

The core stage fueling test Dec. 20 was the penultimate test of the year-long “Green Run” test campaign at Stennis, setting the stage for the core stage hot fire test Saturday.

With the fueling rehearsal accomplished, NASA managers opted to go ahead with stacking the next two segments of the left-hand and right-hand boosters. Those were added on the Mobile Launcher inside High Bay 3 of the Vehicle Assembly Building on Jan. 7 and Jan. 12.

“So far, it’s gone smoothly, and we’ve got the aft segments stacked on the (Mobile Launcher) as well as the aft-centers,” Honeycutt told Spaceflight Now.

With the stacking of the two aft-center segments, the 12-month certification clock will expire in January 2022. Honeycutt said this week that the SLS continues to work toward a launch date at the end of 2021.

The Space Launch System will launch NASA’s Orion crew capsule on an unpiloted mission to the moon, where the spacecraft will enter lunar orbit for a series of checkouts in deep space before returning to Earth for a parachute-assisted splashdown in the Pacific Ocean.

It will be the first launch under NASA’s Artemis program, which aims to land astronauts on the moon for the first time since 1972. A Trump administration goal to perform the next crewed lunar landing by the end of 2024 is unlikely to be continued by the Biden administration, and the scope of technical work and a lack of funding from Congress meant the window was already closing on achieving a lunar landing with astronauts in the next four years.

If the first SLS/Orion flight, known as Artemis 1, the second SLS/Orion mission could launch in 2023 to send four astronauts around the moon and back to Earth. But development of a lunar lander to carry astronauts to the surface of the moon remains in the early stages.

Nevertheless, the first launch of the 322-foot-tall (98-meter) Space Launch System, although years behind schedule and over budget, is a big step on NASA’s effort to return astronauts to the moon. The powerful launcher’s two solid rocket boosters and four hydrogen-fueled RS-25 core stage engines will generate up to 8.8 million pounds of thrust at liftoff, more than the thrust generated by the Apollo-era Saturn 5 moon rocket.

Like the SLS core stage, the twin boosters will be expended on each mission. The shuttle boosters were recovered and reused, and the rocket motors on the Artemis 1 mission include hardware flown on 40 space shuttle missions.

“Our team is locked in and focused on delivering the rocket for a 2021 launch,” Honeycutt said.

But given the history of delays in the SLS program, and problems that often crop up during launch campaigns for new rockets, the risk of a further schedule slip is not insignificant.

Honeycutt said engineers are making measurements and collecting data as ground teams stack each segment of the Artemis 1 boosters inside the Vehicle Assembly Building. The data could help NASA and Northrop Grumman, the booster manufacturer, extend the certification of the rocket motor joints beyond 12 months.

“We’re just having to be very conscious as we move through the stacking, making sure we take time to assess the data and making sure that we’re ready to go stack the next segment,” Honeycutt said. “And then that gives us the best opportunity to do some sort of a life extension on the booster stacking in the event that we need that.”

Email the author.

Follow Stephen Clark on Twitter: @StephenClark1.