STORY WRITTEN FOR CBS NEWS & USED WITH PERMISSION

SpaceX and its visionary founder Elon Musk win the lion’s share of public attention in the commercial rocket arena, with dramatic, increasingly routine booster landings and spectacular stunts like the launch of Musk’s Tesla Roadster on the maiden flight of the company’s new Falcon Heavy rocket last month.

But arch-rival United Launch Alliance, a much more buttoned-down corporate alliance between Boeing and Lockheed Martin, is responding to the threat posed by the upstart SpaceX with long-range plans to phase out its workhorse Atlas 5 rocket and costly Delta 4 rockets in favor of a powerful, less-expensive launcher known as the Vulcan.

Featuring reusable engines and an advanced, long-lived upper stage, company executives expect the Vulcan to be a major contender in the increasingly fierce slugfest between SpaceX, ULA and other international launch providers.

That battle was center stage Wednesday when the Air Force awarded SpaceX a $290 million contract to launch three Global Positioning System navigation satellites atop Falcon 9 rockets in late 2019 and 2020.

At the same time, ULA won a $351 million contract to launch two Space Situational Awareness Program satellites using an Atlas 5 rocket in 2020, along with a second flight to launch another pair of military payloads.

“I am a big supporter of competition,” ULA CEO Tory Bruno said in a recent interview. “Makes it an exciting time to be in space, you never know what’s going to happen. In my 35 years as a rocket scientist I never thought I’d see somebody just launch a car into space for fun. I’m not sure what I think of that yet. So yeah I’m with you. These are exciting times.”

In one sense, ULA is playing the tortoise to SpaceX’s hare. Musk was first out of the blocks with development of reusable rocket boosters, but Bruno believes ULA’s Vulcan, with reusable first stage engines, makes the most sense financially given current market projections.

He said the Vulcan’s engines represent two-thirds of the cost of the stage. Under ULA’s approach, the engines will be recovered and reused after every flight. SpaceX’s design calls for recovery of the entire rocket stage. Depending on the weight of the payload and the requirements of its orbit, that cannot be done on every flight.

“It boils down to as simple as this: is it better to recover 100 percent of the value of the booster some of the time or only two thirds of the value of the booster all of the time?” Bruno said reporters during a roundtable discussion earlier this week.

“Well, that depends on how often you get a big, heavy payload. We’ve each made market forecasts, and if we’re right, our solution will be economically advantageous. If I’m wrong and they’re right, then theirs will.”

ULA is staking its future on the Vulcan. Equipped with up to six upgraded strap-on solid-fuel boosters, the new rocket will generate some 3.8 million pounds of liftoff thrust.

Out-performing ULA’s current heavy lift booster, the three-core Delta 4, the Vulcan will be able to boost 80,000 pounds to low-Earth orbit or up to 35,900 pounds to the elliptical geosynchronous transfer orbits — GTOs — used by communications satellites bound for operational stations 22,300 above the equator.

The least powerful version of the new rocket, one without any solid-fuel boosters and an advanced upper stage known as ACES, is expected to sell for less than $100 million. The base version of ULA’s Atlas 5 rocket currently goes for about $109 million, Bruno said, while a heavy lift Delta 4 sells for about $350 million.

Even with six solid-fuel boosters and a large payload fairing, the most powerful version of the Vulcan will still cost “more like a quarter or a third of the cost of the Delta 4 Heavy,” Bruno said in the interview with CBS News.

For comparison, SpaceX sells a commercial version of its Falcon 9 rocket for $62 million, according to the company’s website, although the price climbs to more than $90 million a copy for military missions.

A commercial version of the company’s Falcon Heavy rocket, which debuted in February, has a list price of $90 million, but that apparently assumes all three core stages are recovered for reuse. That version of the rocket, according to the SpaceX website, can boost eight metric tons, or 17,600 pounds to geosynchronous transfer orbit.

That’s the version launched last month, roughly equivalent, Bruno said, to a “mid-range Atlas.” A fully expendable version of the Falcon Heavy can lift nearly 59,000 pounds to that same orbit, easily making it the most powerful rocket in the world.

Bruno said he was impressed by the Falcon Heavy and SpaceX’s maturing ability to recover spent rocket stages.

“I’m a rocket scientist, and that was very cool to watch,” he said. “I certainly give credit to Elon Musk for sort of creating more excitement around space than we had a decade ago.”

But this is not a particularly friendly competition. SpaceX’s website brags the Falcon Heavy “can lift more than twice the payload of the next closest operational vehicle, the Delta IV Heavy, at one-third the cost.”

Not so fast, says Bruno.

“Delta Heavy was really designed around the national security, primarily NRO (National Reconnaissance Office) mission set, which has complicated orbits, and it’s optimized for that,” he said. “It goes for about $350 million. It’s a military mission only, I don’t offer it commercially, at least today, there’s no commercial market for a Heavy.”

The Delta 4, designed by Boeing, and the Atlas 5, built by Lockheed Martin, originally were developed for the Air Force as “evolved expendable launch vehicles,” or EELVs, intended to provide assured access to space for high-priority national security payloads.

With government approval, the two companies formed a partnership and the first Atlas 5, carrying a commercial satellite, blasted off in August 2002.

SpaceX launched its first Falcon 9 in 2010 and, after Air Force certification and vocal complaints about ULA’s perceived monopoly in the military space arena, the California rocket builder was cleared to compete for military contracts.

“We’ve been competing now for almost two years in the military market space,” Bruno said before this week’s Air Force contracts were announced. “Falcon 9s are going for about $97 million, $96.5 million, I think, is the most recent one. They’ve won half, we’ve won half. The government discloses the winner’s price because we’re public procurements. So I think we each know what our prices are.”

To compare the Falcon Heavy with the Delta 4, “you want to compare government missions,” he said. “We don’t market (the Delta 4) commercially. So I would look at the Falcon 9 at $96.5 million as a single stick. Scale that up to be a Falcon Heavy, which is a three-core version of that rocket, and whatever that price is is what I would compare to $350 million.

“If you want to take a massively large payload to LEO (low-Earth orbit), that would be the rocket that would do it. If you want to go higher, you might want to fly on a Delta 4.”

But a Falcon Heavy is not made up of three Falcon 9s. It is, more accurately, one Falcon 9 with a modified central stage and two additional Falcon 9 core stages.

SpaceX has said a fully expendable version of the Falcon Heavy, one capable of boosting nearly 59,000 pounds to GTO, would cost around $150 million, less than half the cost of a Delta 4 Heavy.

But ULA says a rocket’s cost is just one factor in a sale. The company also is selling reliability and “schedule certainty.”

ULA has launched 76 Atlas 5 rockets and 36 more expensive Delta 4s without a single failure. SpaceX has suffered one catastrophic in-flight failure in 50 Falcon 9 launches to date and one on-the-pad explosion.

A rocket’s reliability affects insurance rates and meeting a promised launch date means a commercial satellite will start generating revenue as soon as possible. ULA says both of those factors act to reduce the actual cost of a launch on one of its rockets.

Another wild card in the equation is SpaceX’s plan to build an even more powerful rocket known as the BFR, for Big F-ing Rocket, intended for eventual missions to Mars. It is not yet clear where the Falcon Heavy fits into the company’s long-range plans or whether the BFR will be used for the sorts of payloads ULA hopes to launch on its Vulcan.

But the Delta 4-Falcon Heavy debate will be moot soon enough as ULA phases out the Delta 4 and the Atlas 5 in favor of the Vulcan. Bruno said “at least” seven to eight more Delta 4s will be launched between now and the early 2020s while the Atlas 5 likely will fly into the mid 2020s, overlapping with the Vulcan program as the new rocket begins operational flights.

In the meantime, the Atlas 5 also will be used to launch Boeing’s CST-100 commercial crew ship on flights to ferry astronauts to and from the International Space Station. SpaceX also holds a NASA contract to develop a piloted version of its Dragon cargo ship that will launch atop a Falcon 9. Both companies hope to begin routine flights to the station next year.

The maiden flight of the Vulcan currently is targeted for the middle of 2020. Two successful commercial launches are required as part of the government certification process, followed by a required upper stage upgrade to improve performance, either Aerojet Rocketdyne RL10 engines or a different set of engines altogether.

If all goes well, ULA will introduce its new upper stage in 2024, the Advanced Cryogenic Evolved Stage, or ACES, that Bruno says will revolutionize spaceflight.

“This is on the scale of inventing the airplane,” Bruno told reporters during the media roundtable. “That’s how revolutionary this upper stage is. It’s 1900, and I’m inventing the airplane. People don’t even know what they’re going to do with it yet. But I’m confident it’s going to create a large economy in space that doesn’t exist today. No one is working on anything like this.”

The Vulcan will stand 228 feet tall with a first stage powered by two engines provided by either Blue Origin, a company owned by Amazon-founder Jeff Bezos, or Aerojet Rocketdyne. Blue Origin’s BE-4 engine burns methane and liquid oxygen while Aerojet Rocketdyne’s AR-1 powerplant burns a more traditional mixture of oxygen and highly refined kerosene.

Both engines will generate between 500,000 and 550,000 pounds of thrust and two will be used to power the Vulcan’s first stage. Bruno said ULA is nearing a decision on which engine to employ but would not provide any sort of timetable other than to say the company would announce its choice “soon.”

“They’re both good engines,” he told CBS News. “They both use the what we think of as a very advanced Russian engine cycle, an oxygen-rich stage combustion that the U.S. has never, ever had, and we now will. They just use two different hydrocarbon fuels as you know, one is kerosene and one is methane.”

Both engines “have a lot of additive manufacturing content, which takes that Russian technology and makes it a lot more manufacturable and really updates it to modern standards. So they were both good engines. They are both, you know, hitting their marks and where they planned to be. That’s probably all I can say.”

Whichever engines are used, the Vulcan first stage is being designed with reusability in mind. But unlike SpaceX, which can recover it’s Falcon 9 first stage intact with a rocket-powered return to landing on shore or on an off-shore droneship, ULA only plans to recover the Vulcan’s first stage engines.

ULA plans to begin engine recovery operations after the Vulcan is routinely flying and after the ACES upper stage is implemented.

Bruno said the engines represent two-thirds of the cost of the stage and getting them back every time, with no impact on mission performance, will pay big dividends. SpaceX, in contrast, must use propellant to fly its Falcon 9 stages back to touchdown. Heavy payloads bound for high orbits require most if not all of the rocket’s propellant and in those cases, recovery may not be possible.

As a result, SpaceX’s ability to recover rocket stages depends on its manifest and the orbital demands of those payloads.

“Simplistically, if you recover the old booster propulsively then you can do that part of the time, you get all the value back some of the time,” Bruno said. “Or, you can recover just the engine, which is our concept, and then you get only part of the value back, about two thirds … but you get to do it every single time because there’s no performance hit. So it really turns into math.”

And that math is based on market projections about future satellite builds and the percentage of heavy-weight payloads ULA expects to be launching.

“We’ve made a forecast of what we think the future marketplace will be and said engine recovery is more financially attractive,” Bruno said. “I think SpaceX has made different calculus. And we’ll both go to the market and find out who’s right.”

To recover the Vulcan engines, a small pod housing an inflatable heat shield and a gas generator will be mounted on the bottom of the first stage. After boosting the rocket out of the lower atmosphere, the engines will shut down and the propulsion section will be disconnected, allowing it to fall free.

The heat shield, based on NASA technology, then will inflate using the gas generator, protecting the engines from the heat and stress of atmospheric entry. Once clear of the plasma heating region, a parafoil will deploy to fly the engines to their planned pickup point.

A large helicopter then will swoop overhead, snagging a cable to capture the engine package, which will be lowered to the deck of a nearby salvage ship. A similar technique was used to capture film canisters ejected from Corona spy satellites in the 1960s.

“We’ll separate really the whole back end (of the first stage),” Bruno said. “Then, we’re going to re-enter it behind the NASA inflatable heat shield and then pop a parachute, really a parafoil, because that allows us to make sure we fly to GPS coordinates and a big helicopter will be waiting for it and snag it set it down.”

Recovering the engines non-propulsively will allow the Vulcan to use virtually all of its propellant to put the payload into the best possible orbit “for a pretty modest weight penalty, you know, the weight of a parachute, the weight of the subsystem,” Bruno said.

For a booster, five pounds of inert weight only costs one pound of payload, he added, whereas it’s pound for pound on an upper stage.

In any case, Bruno said the entry environment behind the heat shield is much more benign than what a Falcon 9 experiences with its tail-first propulsive descent and ULA engineers expect engine refurbishment to be a relatively straight forward affair.

“The engines that we’re developing we think are going to be pretty easy to refurbish,” Bruno said. “What we think we’re going to do is get them back, inspect them, for the first few times we’ll likely hot fire them to make sure we know how they’re behaving. If they’re behaving the way we expect, we’ll probably stop doing that. We’ll just clean them up, inspect them and use them.”

Along with recoverable first stage engines, the Vulcan first stage features redesigned plumbing with an internal liquid oxygen feed line, freeing up real estate on the side of the rocket for a sixth strap-on solid-fuel booster.

The Vulcan will be marketed in a variety of configurations depending on payload requirements. If all six SRBs are used, liftoff thrust will be 3.8 million pounds, out performing the Delta 4.

ULA has not yet announced which company will provide the upper stage engines used for the rocket’s initial flights before a planned performance upgrade. But the company expects to introduce the ACES upper stage in 2024.

Featuring up to four hydrogen-fueled rocket engines, ACES will carry three times the propellant of current ULA upper stages, will be able to operate for weeks or months at a time and will enable complex orbital operations near Earth, the moon or beyond.

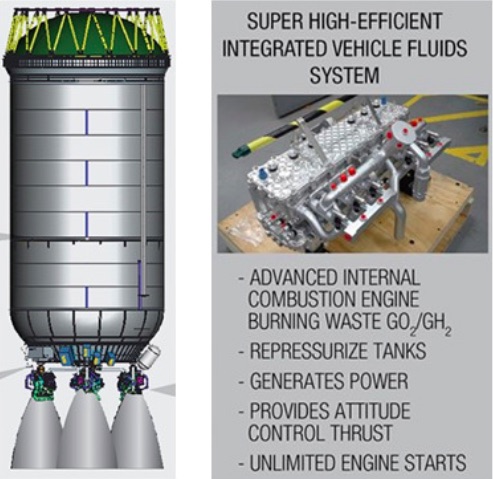

The keys to its performance are ultra lightweight propellant tanks and dual “straight-six” internal combustion engines mounted on the bottom of the stage burning gaseous oxygen and hydrogen produced by the normal “boil off” of propellants in the main tanks.

The 1,000-cc engines, under development at Roush Fenway Racing, will be used to pressurize the propulsion system, push propellants to attitude control jets and generate electrical power, allowing ULA to replace multiple systems with a single solution.

“In a conventional stage, you’ve got to have electrical power, so you have big, long-duration batteries,” Bruno said. “You have to have an attitude control system, so you have typically an entirely separate propulsion system, usually hydrazine. And then you need to pressurize your propellant, which you use (helium) to do.”

Such stages typically have lifetimes measured in hours because the supercold propellants are continually boiling off into gas and batteries lose their power.

ACES solves those problems by using the internal combustion engines to accomplish all of those tasks over an extended period.

“The engine has a generator on it just like your car does so you don’t need the batteries anymore,” Bruno said. “And we’re using the power that comes off of that internal combustion engine to run a compressor and a heat exchanger … that’s putting energy back into the gases. We pipe them back up into the tank and that pressurizes the tanks. So we don’t need helium at all anymore.”

Or heavy time-limited batteries.

“Each one of these (generators) throws off about 60 kilowatts,” Bruno said. “We run a Centaur (stage) at about 10 watts. So now you’ve got 120 kilowatts of electrical power that you could use for other things.”

And the same waste hydrogen and oxygen burned by the engines also can be used to power the stage’s attitude control thrusters, eliminating the need for a separate propulsion system using toxic hydrazine.

“So as long as you’ve got all of this gaseous hydrogen and gaseous oxygen you have propellant,” Bruno said. “So we’ve also developed (oxygen-hydrogen) thrusters and we’ve been testing those as well. They provide the attitude control and … that allows us to delete the entire hydrazine system.

“So that’s how it works. We’ve probably got, I’d say 300, 350 tests on that engine now. It’s pretty cool.”