Space station flight engineer Jeff Williams will send commands Thursday to pump air into an experimental soft-sided module developed by commercial space habitat builder Bigelow Aerospace, expanding the structure to four times its current size in a stepping stone to future orbital destinations.

The Bigelow Expandable Activity Module, or BEAM, is beginning a two-year test campaign at the International Space Station to prove the innovative habitat’s technology is compatible with the stringent guidelines for human spaceflight.

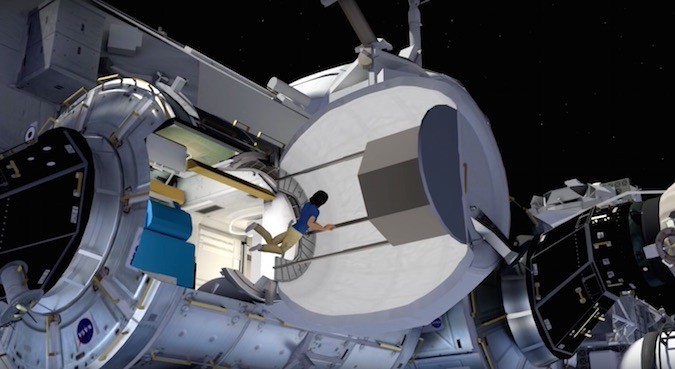

Packed into a depressurized configuration less than 8 feet (2.4 meters) in diameter and 5.7 feet (1.7 meters) long, BEAM will grow like a tent to a width of 10.5 feet (3.2 meters) and a length of 12 feet (3.7 meters) during Thursday’s expansion, the first time such a technique has ever been tested with astronauts in the loop.

“This is our first chance for an expandable (module) to interact with humans on orbit, so we’re really excited,” said Lisa Kauke, BEAM’s deputy project manager at Bigelow Aerospace, a company headquartered near Las Vegas founded by wealthy real estate investor Robert Bigelow.

“The advantage of launching an expandable to space is the packing factor,” Kauke said. “In other words, it packs down really small in the launch vehicle, and it saves on mass, but most importantly volume, and then once it gets on orbit it expands.”

Once enlarged to its pressurized dimension, BEAM will have an internal volume of 565 cubic feet, or 16 cubic meters. That is roughly equivalent to a family-size tent.

Bigelow plans to launch a much larger expandable module as soon as 2020. Called the B330, in recognition of its 330-cubic meter (11,653-cubic foot) volume, the habitat will have life support systems to support up to six astronauts on its own, forming a commercial destination in orbit for researchers, professional astronauts and space tourists.

BEAM is entirely reliant on the International Space Station, but it will verify the expandable technology is suitable for human occupants.

Bill Gerstenmaier, chief of NASA’s human exploration and operations directorate, said that the space agency is eager to see the results of the BEAM demonstration.

“Does it meet all the things that it’s purported to meet? It’s supposed to have better micrometeoroid and debris protection, better thermal protection, better acoustics, and we’ll see if it has those,” Gerstenmaier said in March. “We’ll also understand how to use a fairly large volume, which we have not had experience with.”

A SpaceX Dragon cargo capsule delivered BEAM to the space station April 8. The research lab’s Canadian-built robotic arm pulled the module out of the Dragon spacecraft’s trunk section April 16 and attached it to the station’s Tranquility module.

Ground controllers plan a multi-step process to inflate the module Thursday beginning around 5:30 a.m. EDT (0930 GMT).

Engineers on the ground will send commands to configure BEAM for its expansion early Thursday, including cutting launch restraints that kept the structure bundled up for the trip to the space station.

Astronaut Jeff Williams will open a valve allowing air from the space station’s other modules to gently flow into BEAM, and the habitat’s structural bulkheads will expand to a distance of about 70 inches (1.8 meters), according to Rajib Dasgupta, NASA’s project manager for BEAM.

The expansion will be slow by design.

“That will allow a very controlled expansion of it because we don’t actually which way it will expand,” said Jason Crusan, director of NASA’s advanced exploration systems division. “Our models say one thing, but models are models. So we want to actually very slowly and carefully start that initial inflation, and then once we get up to a nominal pressure, then we’ll actually open up the tanks that are inside of BEAM and bring it up to the full station pressure.”

“After that, we are going to release the air tanks remotely,” Dasgupta said. “There are eight air tanks inside BEAM, and astronaut Jeff Williams is going to push a button and release valves of the eight air tanks. That’s when we introduce air into the BEAM module and take it to full pressure, which is 14.7 psi.”

Space station controllers in Houston will oversee the operation.

Officials want to conduct the expansion procedures when the space station is in sunlight to ensure good video views of the module. Dasgupta said BEAM’s expansion could take up to two hours, spread over two day passes.

“If you knew exactly how (BEAM) was going to grow, and you could force it to a certain curvature of how it expands, then it would have been easier to predict,” said Mark Mulqueen, the space station program manager for Boeing, NASA’s prime contractor for engineering support on the complex. “But since there is some randomness of how it articulates and grows to its full size, that opened up a lot of loads cases that we had to go look at. So we worked with Bigelow and NASA on how to inflate or expand this module.”

Robert Bigelow told reporters before BEAM’s launch last month that the module’s expansion is a key part of the experiment.

“This type of architecture has never been flown before,” Bigelow said. “It has been bound up for over a year waiting for launch. We’re not 100 percent sure of its behavior. It is a testing station. That is the whole point here, in all respects.”

So NASA and Bigelow opted to go for a methodical expansion sequence, allowing engineers to closely monitor BEAM’s response to air pressure.

“We didn’t want to just open the bottles and have it it do what it does, so we have station give it short bursts of station air into the Bigelow module, giving it prescribed volumes of expansion,” Mulqueen said. “That’s how we control it. So we now get to the magnitude we need to get to, and we don’t damage the CBM (BEAM’s connection to the space station).”

Asked about his primary worry during BEAM’s deployment sequence, Bigelow said he will be interested in the performance of seals inside the windowless module.

“My focus is on seals,” Bigelow said. “Whether it’s a submarine or anything that’s in an extreme environment, you want to be able protect that enclosure.

“Whether it’s hatches, bulkheads, or windows, my first first focus is the successful functioning of all of the seal mechanisms,” Bigelow said. “I’m not worried about the hull. I’m not worried about anything to do with that. I’m worried about the interface between metallic systems and soft good systems. It’s a very complex interface.”

Once BEAM opens to its full size, astronauts will enter the module to install lights and sensors to see how it withstands the harsh environment of space.

Bigelow says it will offer protection from high-speed impacts by tiny micrometeoroids and space junk at least equal to the shielding on the space station’s conventional metallic modules.

The habitat is made of a multi-layer Vectran-like material, according to Kauke. NASA used similar materials in the airbags that cushioned the landings of NASA’s Mars Pathfinder, Spirit and Opportunity rovers.

“When the whole BEAM is pressurized, these walls move out and they actually become very rigid, so touching the walls is like touching the walls of your house,” Kauke said.

Sensors inside BEAM will measure the dynamics of its inflation Thursday. Other instrumentation will track temperatures, radiation levels and strikes by micrometeoroids and orbital debris.

Space station crew members will enter the module at least a half-dozen times per year to take samples of the air and surfaces inside BEAM for microbial growth, Dasgupta said. They will also swap out passive radiation monitors for return to Earth for analysis.

At other times, the hatches between the station and BEAM will remain closed.

Bigelow’s expandable module concept has its roots in a NASA project called TransHab, which investigated alternative habitat designs for the International Space Station in the 1990s.

The company purchased the patent to the TransHab technology and sought to commercialize the architecture, launching two sub-scale inflatable spacecraft from Russia in 2006 and 2007. Those missions, dubbed Genesis 1 and 2, performed beyond expectations, Kauke said.

BEAM takes a leap to prove the technology is suitable for human spaceflight.

NASA is paying Bigelow Aerospace $17.8 million for the demonstration.

“It is an important step to us,” Bigelow said. “It really (shows) that NASA has the confidence in our little company to be able to to this.”

Email the author.

Follow Stephen Clark on Twitter: @StephenClark1.