EDITOR’S NOTE: Updated at 6:15 a.m. EDT (1015 GMT) Friday, June 11, after core stage was rotated vertical.

Technicians inside the Vehicle Assembly Building at NASA’s Kennedy Space Center began a delicate, multi-day task Thursday to lift the 94-ton core stage of the first Space Launch System heavy-lift rocket for mounting between two solid-fueled boosters already stacked for a test flight to the moon.

The stacking milestone begins a process that NASA officials say should culminate in a fully-assembled Space Launch System and Orion spacecraft as soon as August. If everything goes on a schedule, a major “if” for a brand new rocket with a history of delays, NASA could move the 322-foot-tall (98-meter) rocket to pad 39B on top of one its giant Apollo-era crawler-transporters in late September for a mock countdown and fueling test.

NASA hopes to launch the SLS and Orion crew capsule on an unpiloted test flight around the moon as soon as late November. The mission, known as Artemis 1, will last more than three weeks and pave the way for the next SLS/Orion mission, Artemis 2, to carry a four-person crew around the moon in 2023.

Artemis missions later in the 2020s will land astronauts near the south pole of the moon using commercially-developed lunar landers. In April, NASA selected a variant of SpaceX’s Starship, a reusable heavy-lift rocket being developed with majority private funding, to land the first Artemis crew on the moon.

But NASA plans to use the government-owned Space Launch System rocket and Orion capsule for the round-trip flight between Earth and the vicinity of the moon, where astronauts will transfer into a lunar lander, such as the Starship, for descent to the surface.

The lifting of the SLS core stage onto its mobile launch platform moves NASA closer to launch of the Artemis 1 test flight.

Two cranes began raising the 212-foot-long (65-meter) core stage off cradles Thursday inside the VAB’s transfer aisle, the cavernous central passageway between the building’s four rocket assembly bays.

The milestone signaled of the start of a slow motion process to lift the core stage high above the VAB floor and rotate the rocket vertical. Before dawn Friday, teams maneuvered the core stage vertical to allow ground crews to disconnect one of the cranes attached to the aft end of the rocket.

That left the rocket handing on a heavy-duty 325-ton to hoist it over the transom into the building’s northeast high bay.

The rocket’s twin solid rocket boosters, each standing 177 feet (54 meters) tall, are already stacked inside High Bay 3 on a mobile launch platform.

The crane will lower the 27.6-foot-diameter (8.4-meter) rocket stage between the two boosters. Once in position, the core stage will be connected to the boosters at forward and aft load-bearing attach points.

The entire lift and mate operation could take several days, according to a NASA spokesperson.

“When we start the lift up and over, it’s about a two-day process by the time we’re soft mated and disconnected,” said Cliff Lanham, senior vehicle operations manager for NASA’s Exploration Ground Systems division at Kennedy. “That includes everything to go up and over, attach to the boosters and be in a position where we say let’s go ahead and take the GSE (ground support equipment) off.”

During launch, the core stage’s RS-25 engines and twin solid rocket boosters will generate 8.8 million pounds of thrust. It can send about 59,500 pounds (27 metric tons) of payload to the moon, more than any rocket operating today.

The ground crew inside the VAB rehearsed the lift and mate procedures in 2019 with a pathfinder structure built to mimic the weight and size of the SLS core stage. But the last time the VAB cranes lifted real rocket hardware in preparation for launch was before the final space shuttle mission in 2011.

“The teams are going to be careful,” Lanham said in a recent interview with Spaceflight Now. “The teams are going to take their time and make sure they’re doing it right. It’ll seem glacial to the outside observer, but there will be a lot going on between inspections, making sure hookups are correct, and actually getting into the lift.”

The hoisting of the SLS core stage comes about six weeks after the rocket rolled into the Vehicle Assembly Building at Kennedy, following an ocean journey aboard a NASA barge from the Stennis Space Center in Mississippi. Ground crews at Stennis test-fired the rocket’s four RS-25 engines for more than eight minutes in March to simulate a full launch profile.

Since the core stage arrived in Florida in late April, teams from NASA and Boeing, the rocket’s prime contractor, repaired dozens of areas of orange foam thermal insulation damaged during the eight-minute test-firing at Stennis. They also touched up cork thermal insulation on the bottom of the rocket’s engine section that charred during the hotfire test earlier this year.

The foam helps regulate temperatures inside the main stage’s cryogenic propellant tanks, which will hold more than 730,000 gallons of liquid hydrogen stored at minus 423 degrees Fahrenheit (minus 253 degrees Celsius) and liquid oxygen at minus 298 degrees Fahrenheit (minus 183 degrees Celsius).

Engineers also identified a few sensors that needed repair on the outside of the rocket. A small fraction of the more than 500 sensors designed to collect data the rocket’s performance and environments debonded during the test-firing.

And ground crews finished installing linear shaped charges along the core stage’s exterior. The charges are part of the flight termination system, which would destroy the rocket if it flew off course and threatened the public.

After completing all the work required while the rocket was horizontal, teams moved the core stage to the north end of the VAB’s transfer aisle Monday and installed a lifting cap, called the “spider,” on the forward end of the rocket.

After connecting two cranes to each end of the rocket, ground crews removed one of the two transporters underneath the core stage Thursday, leaving the rocket partially suspended over the floor of the transfer aisle.

Once teams rolled the other transporter out from under the rocket, the cranes lifted the core stage farther off the ground before rotating it vertical around 3 a.m. EDT (0700 GMT) Friday.

While technicians completed work on the rocket in the transfer aisle, teams inside High Bay 3 configured work platforms and readied the solid rocket boosters for mating with the SLS main stage.

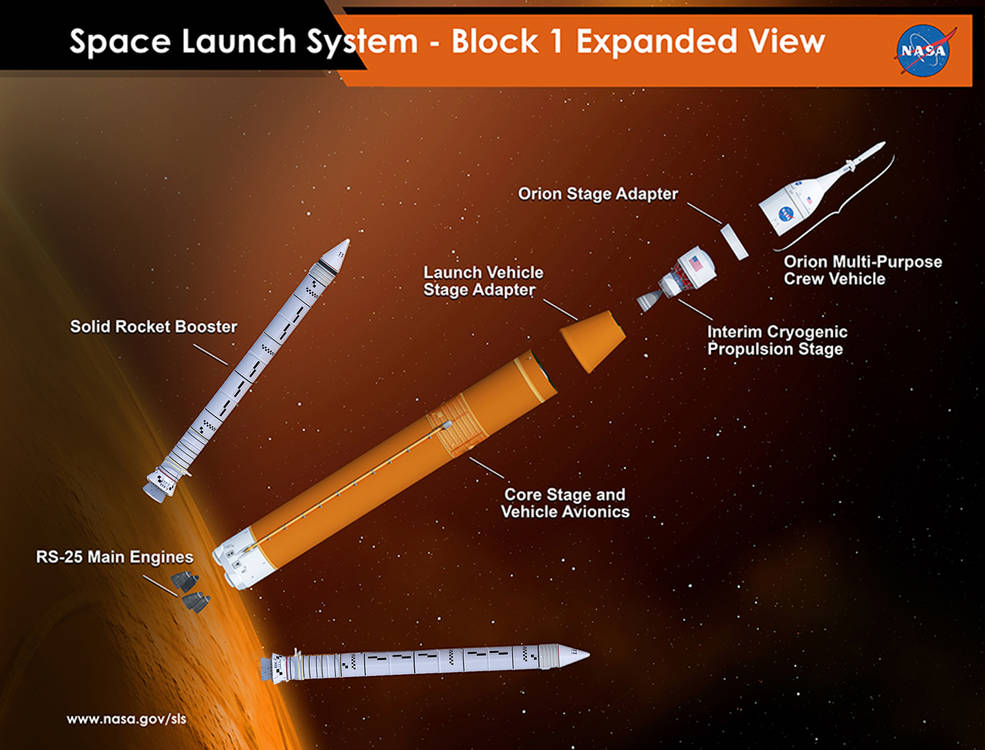

With the core stage in place, Lanham said the pace of stacking will be be “fairly quick.” Next will be the Launch Vehicle Stage Adapter, or LVSA, the interstage structure that will connect the main stage with the rocket’s upper stage.

The LVSA is scheduled to be installed on top of the core stage next week.

Then the Interim Cryogenic Propulsion System, or ICPS, will be added to the Space Launch System later this month in High Bay 3. The hydrogen-fueled upper stage is derived from the second stage of United Launch Alliance’s Delta 4-Heavy rocket.

The upper stage is currently being readied for launch inside the Multi-Payload Processing Facility at Kennedy. When teams in High Bay 3 are ready, the ICPS will ride on a transporter several miles to the VAB to be raised atop the Space Launch System.

“It’s a pretty aggressive stacking sequence that we’ll be following, all in an effort to get us ready and get the umbilicals mated so we can get into our power up and get into our real big test, which will be our umbilical retract test,” Lanham said.

Once the upper stage is installed, ground teams will lift another adapter designed to connect the Orion capsule. Then a structure will go on top of the rocket to simulate the weight of the Orion spacecraft.

That will set the stage for a test to verify the propellant lines, fluid connections, and other umbilicals running between the mobile launch platform’s tower and the rocket can safely release and retract as they will at liftoff.

Then teams will move into structural resonance testing, or modal testing, of the fully-stacked launch vehicle in July. Once that is complete, teams will move the real Orion spacecraft — which will already be integrated with its launch abort system — to the VAB for attachment to the top of the Space Launch System, an event that could happen as soon as early August, Lanham said.

After the practice countdown, which NASA calls a wet dress rehearsal, the SLS and Orion spacecraft will return to the Vehicle Assembly Building for final closeouts, inspections, and ordnance connections.

The next time the rocket rolls out to pad 39B will be around six day before launch, Lanham said.

“We’ll face challenges ahead, he said. “We’re heading into hurricane season. We’ll see how that plays out. It’s the first time we’ve done this, so we’ll run into issues there, but we are absolutely trying to get this launched by the end of the year.”

Email the author.

Follow Stephen Clark on Twitter: @StephenClark1.