EDITOR’S NOTE: Updated at 4 p.m. EST after tensioning of the first sunshield layer. Updated at 8 p.m. EST after tensioning of second and third layers.

Mission controllers started the delicate work of tightening the five razor-thin layers of the James Webb Space Telescope’s sunshade Monday. Managers said the nearly $10 billion observatory is “hunky-dory” after pausing deployments over the weekend to adjust the observatory’s power levels and ensure motors needed for the tensioning are in tip-top shape.

Ground teams at the Space Telescope Science Institute in Baltimore, Maryland, completed tensioning of the largest and hottest layer of the tennis court-sized sunshield Monday at 3:48 p.m. EST (2048 GMT), and immediately started working on the second layer, which was fully tightened at 5:23 p.m. EST (2223 GMT) after 74 minutes of work.

The third sunshade membrane was tensioned over the course of 71 minutes, ending at at 6:59 p.m. EST (2359 GMT), NASA said.

The remaining two layers will be pulled taut with a complex system of electric motors, pulleys, and cables Tuesday, assuming everything goes according to plan.

But managers have flexibility in the schedule, and there’s no rush to push Webb through its remaining deployments, a sequence of events required to transform Webb from its launch configuration into a telescope tuned to register the faint infrared light from the first galaxies in the universe, said Bill Ochs, NASA’s Webb project manager.

“We do not want to burn out our team along the way,” Ochs said Monday in a conference call with reporters.

The work Monday proceeded faster than officials predicted. Ochs said Monday morning the ground team only planned to tension one layer of the sunshield Monday, followed by more tensioning operations Tuesday and Wednesday.

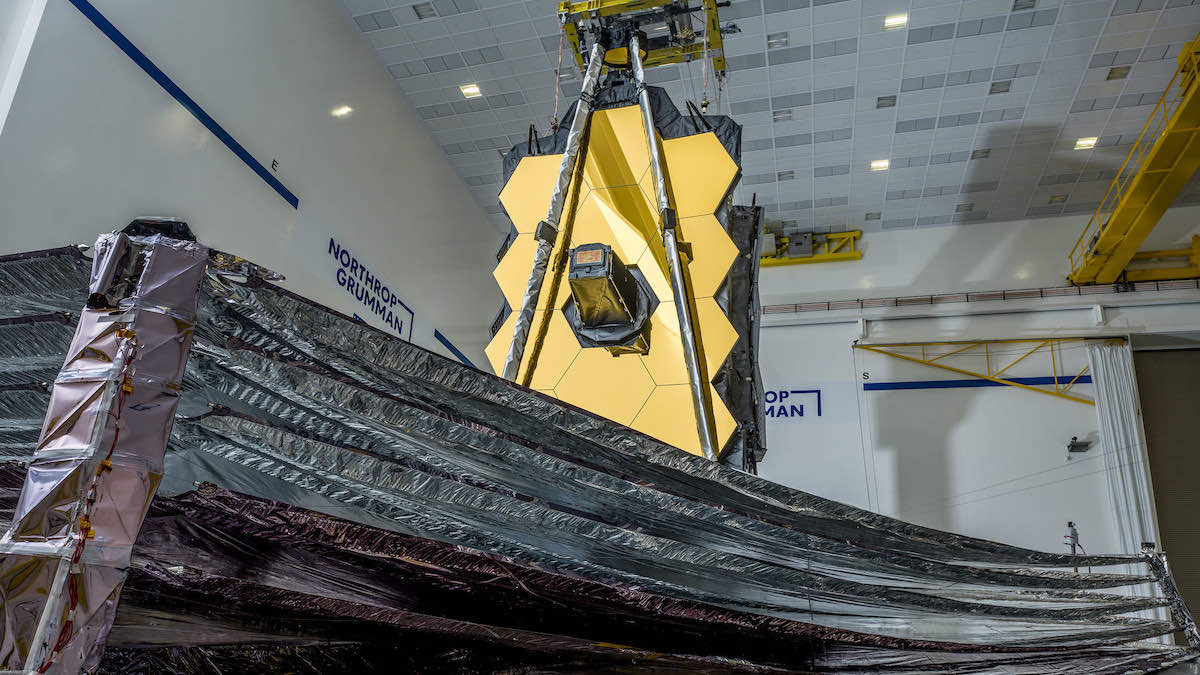

“The membrane tensioning phase of sunshield deployment is especially challenging because there are complex interactions between the structures, the tensioning mechanisms, the cables and the membranes,” said James Cooper, NASA’s Webb sunshield manager, based at Goddard Space Flight Center. “This was the hardest part to test on the ground, so it feels awesome to have everything go so well today. The Northrop (Grumman) and NASA team is doing great work, and we look forward to tensioning the remaining layers.”

The first week of Webb’s mission went like clockwork, but engineers changed the schedule over the weekend to make adjustments to the spacecraft’s power-generating solar array and cool higher-than-expected temperatures on the motors required to pull the sunshade tight.

One of the reasons officials put off tensioning the sunshield was to give ground teams time to “rebalance” Webb’s 20-foot-long (6-meter) solar array to improve its power generating capacity. The change involved adjusting the solar array, made of five individual panels, off its factory settings, according to Amy Lo, a Webb systems engineer at Northrop Grumman, NASA’s prime contractor for the mission.

The solar array was generating enough electricity for Webb, but engineers prefer as much power margin as possible, especially as the power-hungry observatory continues through more deployments and commissioning.

Lo said engineers knew they would reset the array’s operating parameters after monitoring its performance in space. The power throughout from the solar array can depend on a range of factors, including the temperature of the system’s solar cells and regulators feeding power to Webb’s batteries. A hotter solar panel is slightly less efficient at generating power than a cooler panel, Lo said.

“The factory preset makes all of the panels and all of the regulators operate at the same duty cycle (or operating regime), so it’s not very optimized,” Lo said Monday.

“As we got on orbit and understood what temperatures the arrays were operating at, and tracked the load we expected to see, we then went ahead and made the decision that we did want to rebalance the array and set a duty cycle so that each panel of the array … could be optimized to work at their best duty cycle possible.”

The reset Sunday changed the system’s voltage from 58.6 volts to between 65 and 69 volts, Lo said.

“So the change wasn’t much, but it’s what we needed,” Lo said. “Everything is hunky-dory and doing well now. The observatory was never in danger.”

The other technical issue Webb’s ground team addressed over the weekend was with the sunshade tensioning motors.

The motors are critical components needed to drive the sunshade layers to their fully tensioned state. Their temperatures were a bit warmer than expected over the weekend, but still within operating limits.

“As we looked at the temperature of the motors, it did not have as much margin as we preferred,” Lo said Monday. “One way of cooling the motor is to re-point the observatory, so there’s less incident sun on these motors, so they can have time too cool off. So that was executed last night.”

The Webb telescope launched Dec. 25 aboard a European Ariane 5 rocket, and has performed well as it unfolded its solar array, high-gain communications antenna, and two large pallet structures that held the sunshade layers for the ride to space.

Webb extended a tower assembly last week to provide distance between the telescope’s mirrors and instruments, which must be chilled to cryogenic temperatures, and the much hotter spacecraft, with the solar array that needs to be constantly pointed at the sun.

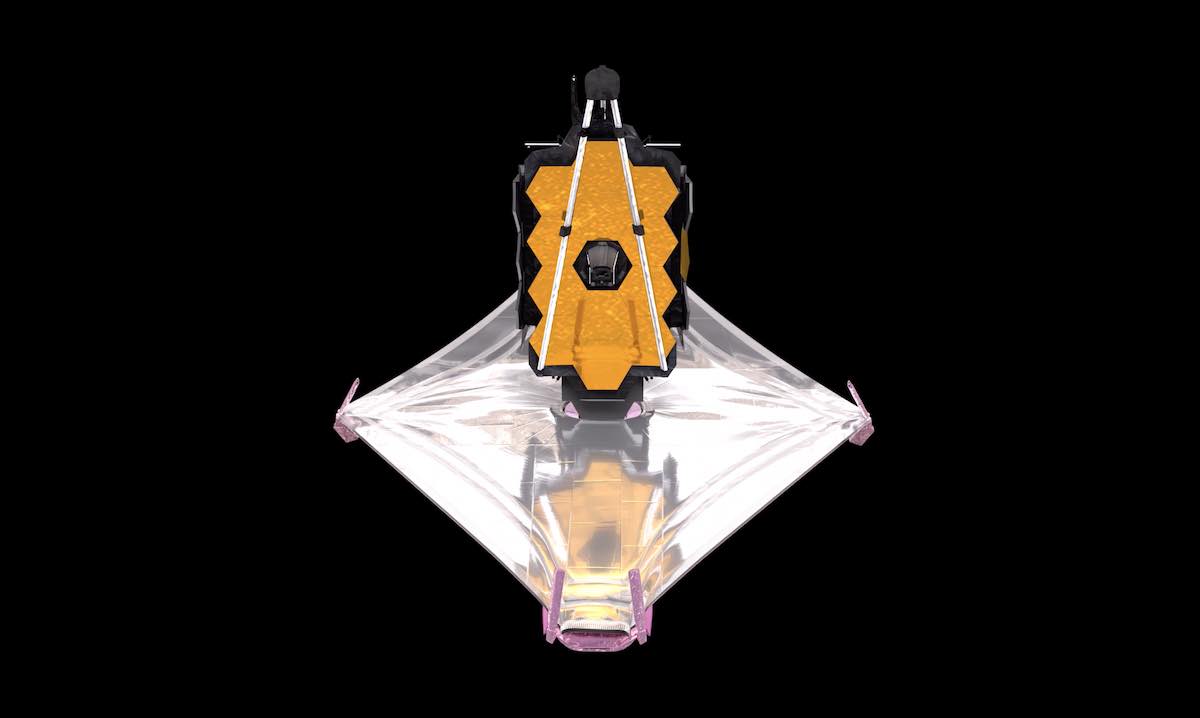

The sunshield is designed to provide a nearly 600-degree thermal gradient between the hot spacecraft and the cold telescope. It has five layers, each as thin as a human hair, made of a material called kapton and treated with shiny aluminum. The two outermost layers have an additional purple-hued silicon coating to aid in reflectivity.

Ground teams uplinked commands for Webb to roll off covers to reveal the sunshield membranes Thursday, then extended two mid-booms out each side of the spacecraft Friday, pulling out the five sunshade layers like sheets on a bed.

“Mid-boom deployment was huge,” Ochs said. “That was really a huge achievement for us. The tensioning of the layers is the next big step that we go through.”

Before Webb’s launch, most NASA managers and astronomers gave the same answer about the most stressful moment of the mission: Sunshield deployment.

“The sunshield is one of these things that is almost inherently indeterministic,” said Mike Menzel, Webb’s mission systems engineer at NASA’s Goddard Space Flight Center in Maryland, in a press conference before launch. “NASA is used to deploying rigid beams on hinges, because they’re deterministic, you can determine how they move.”

“Given that there are 40 different major deployments, and hundreds of pulleys and wires, the whole thing makes me nervous and will until its fully deployed,” said John Grunsfeld, an astrophysicist, former astronaut, and head of NASA’s science mission directorate from 2012 until 2016, a key period in Webb’s development.

Menzel compared predicting the behavior of the sunshield layers to guessing what a string will do when you push it on a table top.

“So it is with the membranes of the sunshield,” he said. “So we can’t really predict their shape, but we can constrain it. “We can try to prevent it from going in places that we don’t want it to go, places where it could snag or tear, or maybe impede the deployment of other members.”

Each layer of the sunshield is slightly different in size and shape, created using thermally bonded sections of kapton with around 10,000 seams, according to Krystal Puga, Webb’s lead spacecraft systems engineer at Northrop Grumman.

There are reinforcement strips, or rip stops, to contain any tears or holes, and metallic ribbons giving the kapton some structural support.

“Once we get the sunshield out, that’s great, but then we have to sort of tighten it up,” said Keith Parrish, NASA’s commissioning manager for Webb, in an interview before launch. “All five layers have different points around them where they’re connected up, and then we’ll pull on cables in each one of those corners to actually tighten up the sunshield.”

“The very last step is super important,” Puga said. “We need to tension all of the membranes using a series of pulleys and cables to create the separation between each of the five layers.”

The tensioning will separate each of the five ultra-thin membranes, spacing them a few inches at the center and a few feet at the outermost edges. The tapered spacing helps allow heat from the sun to reflect between the layers, and eventually radiate back into space.

Six motors will pull on a quarter-mile of cable on the left and right side of the sunshield, and at the front and back, to tighten up the five kapton layers. If the motors get too hot, teams can send commands for Webb to halt the motion.

“JWST deployment is designed to stop any any point,” Lo said. “We can stop at any time and do a little bit of reverse, and then keep going. That is a basic fundamental design driver that we have in our requirements.”

The movement will be slow, with guides to help make sure there are no snags or tears. The deployment of the mid-booms Friday worked exactly as designed, with 107 critical release mechanisms activating to allow the solar blanket to unfurl.

“The observatory is designed very carefully to be snag-free, and we have tested this multiple times on the ground,” Lo said. “Given that our telemetry matches the ground testing, we are expecting to have smooth sailing.”

Ochs said once all five sunshade layers are fully tensioned, the mission will have “retired somewhere between 70 and 75%” of the 344 single-point failures identified before launch. Those 344 potential failure points cover critical devices and components, without backups, that have to work for Webb to complete its mission.

Webb’s instruments and telescope need to be super-cold to make them sensitive to infrared light. And astronomers want to observe the cosmos in infrared wavelengths because it allows them to see the oldest galaxies, whose light waves have been stretched by the expansion of the universe.

Infrared astronomy also reveals star-forming regions obscured by clouds of gas and dust opaque to telescopes that see in visible wavelengths, the kind of light detectable by the human eye.

Mark McCaughrean, an astronomer at the European Space Agency, tweeted last week that infrared astronomy with a warm telescope “is like trying to observe in the visible in broad daylight with a telescope made of light bulbs. Possible, but you won’t see faint things very well.”

Once the sunshield is deployed and tensioned, ground teams will turn their attention to unfolding Webb’s huge primary mirror to its full 21.3-foot-wide (6.5-meter) diameter, the biggest telescope ever sent into space. A secondary mirror, mounted on a tripod-like boom apparatus, also needs to move into place to reflect light into Webb’s instrument module, and ultimately onto detector arrays to make images and spectral measurements.

Those events are scheduled to begin at the end of this week, Ochs said, a few days later than originally planned after the pause in deployments over the weekend.

Webb is cruising toward its operations post in a halo-like orbit around the L2 Lagrange point, a gravitational balance point nearly a million miles (1.5 million kilometers) from Earth. Webb’s arrival in that orbit is expected around Jan. 23, followed by five more months of instrument activations, optical focusing, and other calibration work before the science mission begins.

Email the author.

Follow Stephen Clark on Twitter: @StephenClark1.